- Solutions

- Extraction systems

- Complete plant construction

- Extraction and filter systems

- Spare parts

- Explosion protection

- Filter elements

- Mobile extraction units

- Oil and emulsion mist separator

- Dust collection elements

- Accessories

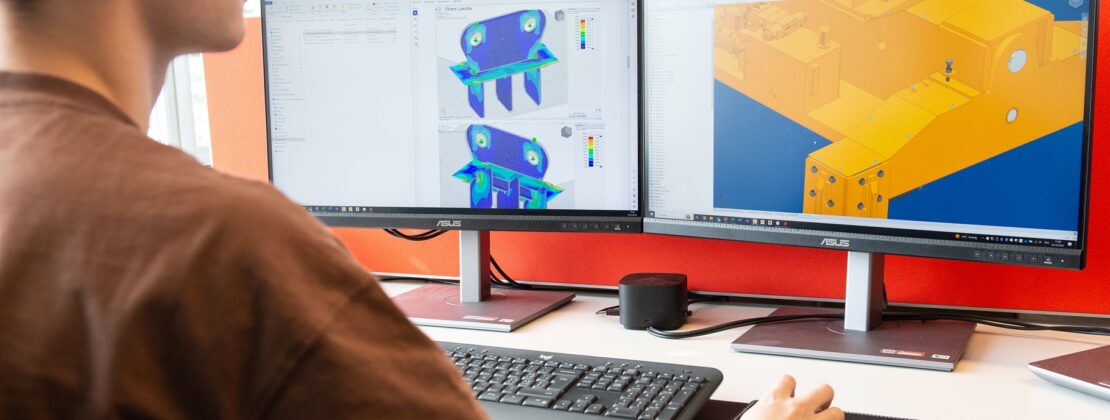

- Industrial steel construction

- Plant platforms-machine staircases-industrial equipment

- Container construction

- CE conformity and load tests

- Chassis and vehicle frames

- Lifting equipment and heavy-duty transport racks

- Impeller and fan welding

- Machine frames and housings

- Metal filter by L+M AG

- Modular construction + industrial ventilation

- Special machinery and equipment

- Steel components

- Industry solutions

- Total 96,000 kg

- Transport frame 11,000 kg, length 11.0 m, width 4.5 m

- 4 cm clearance between capping stack and flyer in width

- Executed in S690 -> Minimum weight of the frame

- Approved by Antonov Airlines and Volga-Dnepr Airlines

- Acceleration values up to 3.5 g

Our sturdy transport frame ensures reliable use of capping stacks.One order from OSRL (BP, Shell, Total, Chevron, ExxonMobil etc.) was to design and build a transport rack that would enable the capping stacks to be transported by air. These capping stacks were developed to seal wells with leaks on the seabed. Only if the capping stacks can be transported from the sites in Norway, Brazil or Singapore to every well in our oceans within a few hours can oil disasters such as the Deepwater Horizon 2010 be prevented. The challenge was to find an efficient solution. Space was extremely tight, weight had to be kept to a minimum, and the static and dynamic requirements of the aircraft and capping stack had to be taken into account. L+M AG managed to successfully implement this technically demanding project.

Specification

- Extraction systems